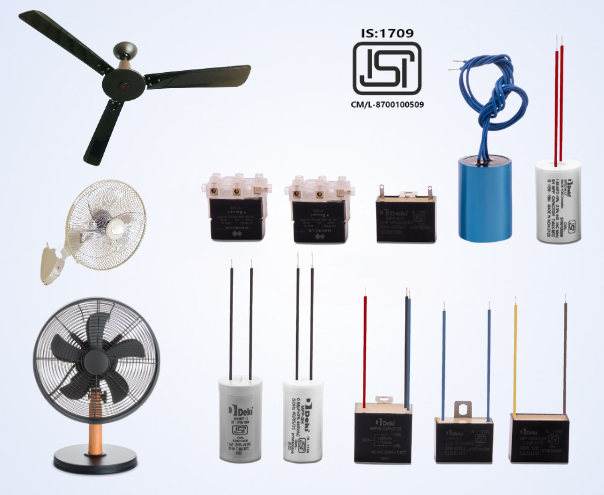

Our capacitors comply with stringent standards, ensuring reliable performance and enhanced fan motor efficiency.

-09082402355067.png)

Innovation is key to growth at Deki Electronics. We develop new products, provide solutions to our customers and work not as mere manufacturers but as partners.

Single-phase induction motors, commonly used in ceiling fans, require auxiliary winding capacitors to start. The Fan Motor Run Capacitor is crucial, as improper capacitance can lead to irregular rotation, noise, increased energy consumption, and overheating.

Key Developments:

Fan Motor Run Capacitor Specifications:

Testing Specifications:

Our capacitors comply with stringent standards, ensuring reliable performance and enhanced fan motor efficiency.

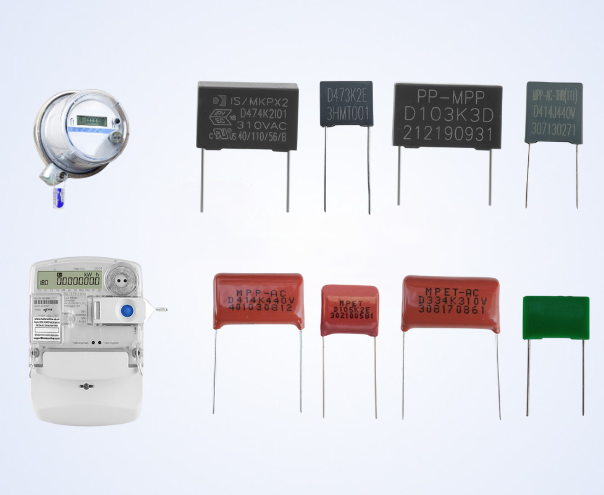

High Capacitance Stability MPET Capacitors

These capacitors, designed for AC voltage and low frequency applications, feature metallized polyester film with non-inductive winding and flame retardant epoxy coating. With exceptional performance in high temperature and humidity, they ensure reliable operation with minimal capacitance drop.

Specifications:

These capacitors excel in humid environments, making them ideal for energy meter applications.

Requirement for lamp circuit capacitor in high wattage CFL

The critical section of a CFL is the lamp circuit since it has to withstand high voltage spikes with high frequency during the ignition phase of the CFL.

Polyester Inductive capacitors are generally used in low wattage CFL lamp circuits where the wattage is less than 24 watts. For high wattage CFL lamp circuits MPP/MPP capacitors are generally used as inductive capacitors cannot be used due to inherent design issues.

PET inductive capacitors have a film foil construction with aluminium foil as electrode and polyester (PET) film as dielectric. While the aluminum foil electrode thickness is 5-6 microns the dielectric film thickness depends upon the voltage rating of the capacitor. In this construction type, both the aluminium foils are parallel to each other and are separated by a dielectric. There is a probability of short circuit when high voltage spikes occur owing to the possibility of weak points in the dielectric.

At Deki, we have been successful in developing a unique capacitor that not only withstands the high voltage spike at ignition but also has self-healing properties. This self-healing inductive capacitor is an ideal choice for high wattage CFLs.

-3107241048039-13082410102274.png)

At Deki Electronics, our commitment to innovation ensures that we not only meet but exceed industry standards, delivering products that set benchmarks for performance and reliability.

In case of any queries please contact us at info@dekielectronics.com

Film Capacitor

Manufacturer

of Legacy

Members

Team

Recognized by

the Govt. of India